Prototyping the Flat Pack Sandbox

Meeting Notes: 01/21/16

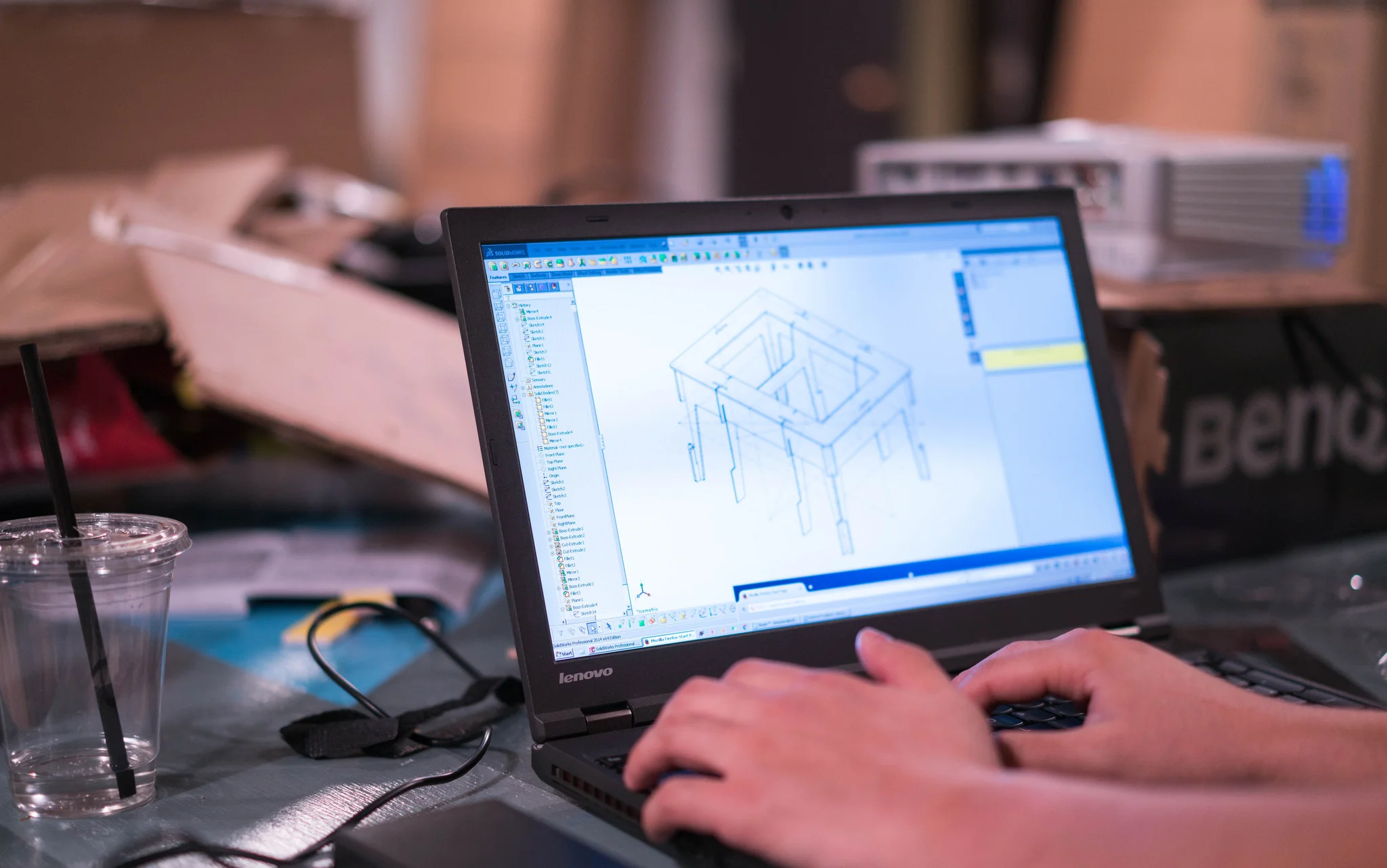

We've made the decision to attempt a design without any hardware, creating an entire piece of furniture using just sheets of plywood. In order to create a piece of furniture out of a flat sheet of material we first need to break it into sections that can be fitted together. Once we have those sections we "nest" them on a sheet. Nesting is a process that is a bit like doing a puzzle in reverse, parts are rotated and flipped in order to fit as many as possible on a single sheet of plywood. In order to test the viability of some of our plywood to plywood connections we came up with a small scale version of the final design. "Small scale" may be a misnomer as the prototype is built to full size in every way with the exception of the opening for our sand tray. Constructing a prototype like this allows us to test the working height of the table and the structural capabilities of the connections without going to the full expense of fabricating the full size final object. In this case we were able to fit our entire prototype on a sheet of 4' x 8' plywood with relatively minimal waste material.

We're happy with the ease of assembly of the parts and pieces but we did identify a few areas that were cause for concern. Because of the way the legs are constructed we have a few elements that could potentially break off in a rough and tumble elementary school environment. To solve these issues we're designing additional pieces of plywood which will "key" into the leg and provide additional stability while create a more robust leg.

After we put the prototype together at our last meeting we investigated the design of the overhead structure which will house both the projector and the Kinect sensor. While we've done so in the past, we've made the decision not to mount the projector vertically this time out of a concern for that a vertical install might significantly shorten the projector lifespan. Mounting the projector horizontally means we'll need to use a mirror to reflect the image onto the table below. In early testing we've found that our short throw projector needs a large hole in the over structure. We spent a fair amount of time massaging the location of the projector, mirror and kinect sensor to verify all three can fit within the tight confines of the overhead compartment.

We're using the scrap plywood from each sheet to construct tools for sandbox play.

The plywood will need a finish to prevent it from weathering over its life so we selected Rubio Monocoat for our prototype. Rubio is a hardwax oil finish with zero VOCs, VOC is short for volatile organic compound, elements which are both harmful to the environment and harmful to the installer. Hardwax oil has another significant advantage over a stain, an oil can be re-applied over any scuff or scratch without having to sand the whole area and re-do the piece. While hardwax oil traditionally isn't the most durable, we've found both Rubio and OSMO finishes to perform decently in high traffic areas. In this case we're attempting to balance durability concerns with a strong desire to create a piece of furniture that doesn't introduce harmful elements to a school environment. The tool above and the portion of the leg below both received a single coat of hardwax oil, you can see that the grain of the wood is retained and the color warms slightly but ultimately retains its original "clear" look.

Each piece will receive a part number, we're experimenting with various labeling systems and font sizes.